Knitting Machines

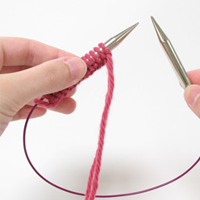

Also called the knitting frame, knitting loom and hand knitting machine, the knitting machine is one of the most interesting gadgets of the modern times. This machine works on the application of a fixed bed of hooked needles mounted together. These needles are used for knitting different patterns of fabrics. The basic components of a knitting machine are a needle bed, yarn guides and a carriage.

Knitting machines can be powered by a motor or can be manually operated. Different patterns of stitches on a cloth can be created by hand manipulation of needles or with mechanical punch cards, computers, electronic pattern reading devices and push-buttons and dials. The motor-powered ones are ruling the roost today.

Knitting machines can be divided as the ones used for domestic purposes and the high-profile ones used in industries. Both the domestic and industrial models of these machines have either flat or circular beds to produce rectangular or tubular fabrics. Flat-bed knitting machines come in two types-single bed machines and double-bed machines. The two parallel beds of a double bed knitting machine produce purl and plain rib fabrics, as also a variety of multi patterns.

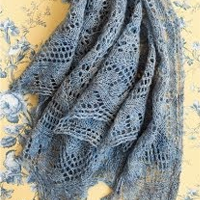

The weft knitting method used in domestic machines produces fabrics similar to the hand-knitted ones. These knitting machines work an entire row of loops in a single go. They are easy to operate and save a considerable amount of time. They produce a much more even-textured fabric, as compared to the fabric that is hand-knitted. Even a person with average creativity can produce a variety of patterns using the knitting machine.

Most domestic knitting machine models produced in the late 20th century use up to 200 latch hook needles to hold the stitches in a normal or bulky sized needle. Every consecutive stitch is produced by passing a carriage or cam box across the bed of needles causing needle movements. Alternative selection methods like punch cards make the desired needles pass through the cam box by alternate pathways.

Knitting machines are highly useful and perform many functions that a person cannot perform through manual knitting. Besides, they save a lot of time and produce knit patterns in several varieties. The stock stitching methods used by these machines perhaps produces the simplest patterns. Pullovers are generally knit by using the method of stock stitching.

The next easy stitch pattern used by these machines is “striped stock stitch” whereby new colors are used in every row. The machine should knit an even number of rows before changing the color. Machines can stitch two colors in each row by using the “Fair isle” pattern of stitching. They use the “tuck stitch” method of knitting to incorporate two or three colors in a fabric. These machines knit thicker fabrics using the “knit weaving” method.

A variety of knitting machines with varying applications are available in the market. In fact, a few of these are designed especially for children. Gone are the days when a person would take ages to knit a simple sweater.

The knitting machines surely have added a lot of fun and color to our lives.